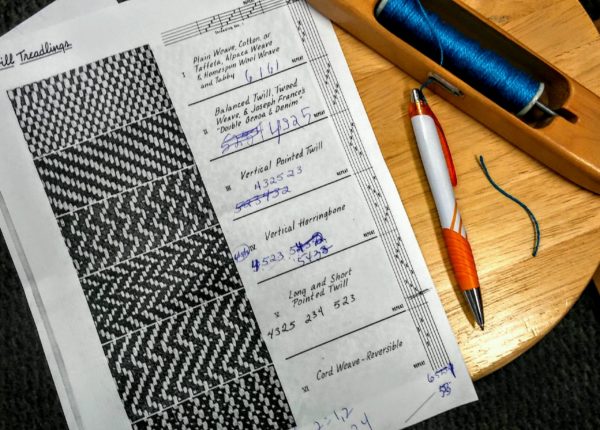

Warping a loom this size was an arduous task, requiring several hours. Passing one thread at a time through the metal dents. Once warped, we were given the “draft” for our sampler. The draft is the coded patterns, and we had 2 pages of them, all giving different results. The floor loom had pedels, or treadles, on the floor that were tied to the heddles. Pressing on a pedel raised the assigned hedels and created the “shed”, or space, for the shuttle to pass through. The shuttle houses the weft, which are the horizontal threads. The table model loom had levers on the side to raise the heddles, instead of treadles. Once we were finished setting up, LET THE WEAVING BEGIN!!